In the world of construction and infrastructure development, ready mix concrete plays a pivotal role as one of the most versatile and widely used building materials. The process of producing and delivering ready mix concrete is a well-coordinated symphony of logistics, and at the heart of this operation lies an unsung hero – the dump truck.

These workhorses of the construction industry are indispensable to the ready mix concrete business, facilitating the efficient transport of materials from production plants to construction sites. In this article, we explore the vital role dump trucks play in the ready mix concrete industry, with a particular emphasis on the importance of adhering to weight regulations to ensure safety and optimal performance.

1. The Foundation of Ready Mix Concrete: Aggregates and Cement

Ready mix concrete is a composite material composed of three primary ingredients: cement, aggregates (such as sand, gravel, crushed stone), and water. To produce high-quality ready mix concrete, the proper proportions of these components must be meticulously measured and mixed. This is where scales and dump trucks come into play.

2. Transporting Raw Materials to the Batching Plant

Before the mixing process begins, the essential aggregates (sand, gravel, or crushed stone) and cement are transported to the batching plant, where they are stored in silos or bins. Dump trucks serve as the workhorse in this crucial first stage. They collect raw materials from quarries or aggregate production sites and transport them to the batching plant. The efficiency and reliability of dump trucks in this process directly impact the overall production capacity and smooth functioning of the batching plant.

3. Precise Measurement and Mixing

In the ready mix concrete business, accuracy is paramount. The right mix of cement and aggregates must be precisely measured to produce concrete with the desired strength, durability, and other essential properties. Overloading dump trucks with excessive pounds of rock, sand, or cement can disrupt this delicate balance, leading to inconsistent concrete quality and potentially compromising the integrity of structures.

4. Load Capacity and Weight Regulations

Dump trucks come in various sizes and load capacities to accommodate different project requirements. It is crucial for ready mix concrete companies to understand and comply with weight regulations to ensure road safety and avoid penalties. Overloading dump trucks not only poses a risk to the driver and other road users but also accelerates wear and tear on the vehicle, leading to increased maintenance costs and potential downtime.

5. Road Safety and Compliance

In many regions, there are strict weight restrictions for commercial vehicles, including dump trucks, to ensure safe and efficient transportation. These regulations are put in place to protect roads and bridges from unnecessary stress and damage. Overloaded dump trucks can cause significant wear to road surfaces and increase the risk of accidents due to reduced vehicle stability and braking capabilities.

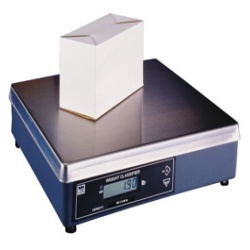

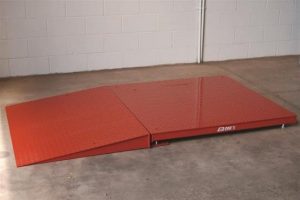

To maintain road safety and compliance, ready mix concrete companies should implement robust weighing and load management systems. This involves installing heavy duty 70×11 electronic truck scales to accurately measure the weight of the loaded vehicle before it hits the road. Drivers can drive over the scale empty, then have their truck loaded with sand, and then obtain a fully loaded weight. The company would now have a weight ticket that shows the gross weight, tare weight, and net weight enabling drivers and operators to optimize the load while staying within legal limits.

6. Optimizing Transport Efficiency

Transportation costs can be a significant portion of the overall ready mix concrete production expenses. Maximizing the efficiency of transport operations not only reduces costs but also minimizes the environmental impact associated with fuel consumption and emissions. Dump trucks should be strategically deployed based on the distance to construction sites and the demand for concrete. Utilizing GPS and route optimization software can further enhance transport efficiency, reducing travel time and fuel consumption.

7. Just-in-Time Delivery

Ready mix concrete is often produced and delivered in a just-in-time manner, which means that the concrete is mixed and transported to the construction site as soon as it is needed. This requires a well-coordinated fleet of dump trucks that can respond promptly to customer orders. Timely delivery is crucial in construction projects to avoid delays and ensure seamless progress on site.

8. Ensuring Material Integrity

Apart from adhering to weight regulations, dump trucks also play a crucial role in maintaining the integrity of the raw materials during transportation. The aggregates must be free from contamination and excessive moisture, as these factors can adversely affect the quality of the ready mix concrete. Dump trucks with appropriate covers and sealing mechanisms protect the materials from environmental factors during transit, preserving their quality and performance.

9. Navigating Challenging Terrain

Construction sites are not always located in easily accessible areas. Dump trucks are designed to navigate challenging terrains and deliver materials to even the most remote locations, ensuring that concrete can be produced and delivered wherever it is needed.

10. Enhancing Productivity and Profitability

Efficient dump truck operations directly contribute to the productivity and profitability of the ready mix concrete business. By ensuring timely deliveries, accurate measurements, and compliance with weight regulations, companies can enhance customer satisfaction and build a reputation for reliability. Furthermore, optimized transport operations lead to cost savings, which can be reinvested in equipment upgrades, workforce training, and business expansion.

Final Thoughts

Dump trucks are the unsung heroes of the ready mix concrete industry and play a critical role in the production and delivery. Their efficient and safe operation is essential for maintaining product quality, adhering to weight regulations, and ensuring timely deliveries to construction sites. Driving the dump truck across the truck scale empty and then fully loaded, provides companies and drivers with the information they need to know regarding net weight, tare weight, and gross weight.