Our local scale calibration and repair customers throughout the central sections of North Carolina are very important to us. We typically stock 90%+ of the standard replacement scale parts that they may need.

However, if you have certain types of scales that aren’t as common or if you have a large number of scales or load cells at your facility… then it can be a smart strategy to keep some spare parts on hand to minimize any downtime. Call us today (919) 776-7737 to determine what replacement scale parts and hardware you need.

If your business relies heavily on your scale(s), then it’s imperative to stock some spare parts to minimize unplanned downtime. Downtime can be a real problem. Especially for certain businesses and at certain times.

Our suggestion is to contact our scale repair & service department and discuss your scales and down time and identify any spare parts that are really important or any spare parts that are difficult to obtain.

Unfortunately, customers often don’t think about downtime and potential failures until it’s too late. This year, we’ve seen some scales that were down for weeks while they wait for replacement parts to arrive from the manufacturer. This is why we encourage you to contact us to determine what items you need to stock.

Supply Chain Issues & Longer Lead Times!

You’ve likely experienced this in your business and we certainly have as well. Between rising prices and labor shortages and continued medical issues, it’s greatly affected the manufacturing and logistics industries. We have seen parts that used to be a 2 day lead time, turn into a 2 month lead time. This is why it’s important to contact us today and discuss what item(s) you need to stock so you can experience the least amount of down time as possible.

These are real concerns that in the past we haven’t had to think much about. However, with certain lead times at record levels… it just makes good sense to plan.

How much money could you potentially lose if your scale is shut down for a couple weeks? What about a couple of months? When you think about it in those terms, if can sometimes lessen the burden of spending a few thousand dollars to keep some spare scale parts on your shelf.

Which Spare Replacement Scale Parts should I Keep on my Shelf to Minimize Unplanned Downtime?

The truth is that spare parts can be expensive to keep on your shelf. We see this every year when we analyze our inventory and determine what items sold and what items collected dust.

And, as mentioned earlier, we stock A LOT of replacement scale parts like load cells, weight indicators, main boards, etc… But, the truth is that we can’t possibly stock every single spare part that every single customer of ours might need. That’s why it’s important to discuss this with our service department and determine what item(s) we feel you should stock.

This will cost you some money but we would argue it’s still not as expensive as a few weeks of unplanned downtime with a broken down truck scale. It goes without saying, but this suggestion regarding spare parts also needs to factor in how important a particular scale is to your business.

For example, if you are a metal recycler, one broken floor scale might be easier to manage since you likely have several other floor scales you could use. However, if you have a broken down truck scale and that’s the only truck scale you own, that item would be much harder to do with out. In our opinion, if you want to reduce potential down time… you might want to stock the following items:

Replacement Weight Indicator

Digital Weight Indicators are items that often break or get damaged on job sites. Sometimes the damage is through lightning, while other times it’s from being knocked off a desk and dropped to the floor or perhaps being run over or hit. Other times “nobody knows what happened“….. In any of these scenarios, the weight indicator is a very important component to a scale system. Without a functioning scale controller, your employees can’t see the actual weight on the scale platform.

To take it one step further… some companies use very sophisticated weight controllers that are programmed for various tasks like truck in/out or truck storage, batching, etc… Those scale indicators need to function and if they fail, there needs to be a replacement available ASAP. For applications like this, it can be a good idea to stock a spare indicator with the custom software installed.

Replacement Scale Boards

Boards are one of the most essential components to a scale. These boards connect all of the components required to power the scale. It’s smart to have the main board, display board, analog output board, summing board(s), remote display main board, etc…. This will vary depending on the customer and which scale(s) you have.

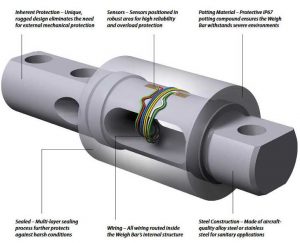

Replacement / Spare Load Cells

We have to include load cells on this list since they are so prevalent in most weighing systems. However, in a lot of cases, we do have stock for most standard strain gauge load cells. This is a great example where we recommend contacting us and discussing what we have in stock and what we recommend that you stock. For example, of the past several years there have been multiple new digital truck scales available which take a digital load cell, cables, and digital weight indicator. Similar challenges exist with hydraulic truck scale replacement parts as well.

Bottom line:

if you have a scale or multiple scales that are very important to your business process, then you need to contact us and discuss recommended spare parts and what we stock versus what we suggest that you stock.

A little forward thinking can minimize the unplanned downtime and it could mean the difference between a few hours of downtime or multiple weeks without a scale.

And these spare parts discussions (they can be phone calls or emails) probably need to happen every year since things change. Items become obsolete, new products get purchased, etc…