Optimal inventory levels, reduced storage costs and satisfied customers are all achievable through effective inventory management. This guide will provide insights and tips on how to implement the necessary steps for successful implementation of this process so that your business can run smoothly with improved efficiency.

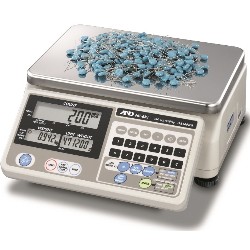

Keywords such as ‘inventory management’, ‘effective inventory management’ and ‘inventory levels’ remain relevant throughout our discussion in order to ensure beneficial outcomes from implementing these practices correctly. Of course we recommend using counting scales when practical for maintaining accurate inventory counts on a regular basis.

Important Points

-

Inventory management is essential for businesses to effectively track and control stock levels, ensure customer satisfaction, and optimize costs. You don’t want excess inventory but you also don’t want no stock or long lead times (supply chain management).

-

Different types of inventory systems range from manual spreadsheets to automated solutions such as RFID tags.

-

Techniques such as EOQ, ABC Analysis & JIT Inventory Management can help minimize storage costs while ensuring accurate stock counts through software implementation.

Understanding Inventory Management

Inventory management is an essential part of any profitable organization’s functioning, managing and controlling stock amounts to guarantee satisfaction for customers while minimizing costs. Companies have a large selection of options from traditional manual systems to sophisticated perpetual inventory control techniques available in order that they can ensure optimal inventory administration.

Now let us explore the importance of inventory management as well as all of its primary components as part of overall inventory management tools assortment. Appropriate stock level tracking plays a huge role when it comes to guaranteeing efficient operation with minimal expenses involved. Companies must turn their attention towards reliable inventories if they are looking for success overall

The Importance of Inventory Management

In order to meet customer demand, prevent stockouts and keep up efficient operations, effective inventory management is essential. A well-crafted system of managing inventories can be the determining factor in business success for companies big or small alike. By accurately tracking their inventory levels, businesses will both ensure no missed sales opportunities nor dissatisfying customers experiences due to a lack of availability when fulfilling orders occur at any time.

Insufficient approaches towards tackling this issue could lead directly into an array of adverse outcomes: lost revenues from missed chances, dissatisfied customers via declining service quality, possession and needlessly storing unnecessary items leading onto hefty storage expenses as ultimate consequence – all being grounds strong enough to make it imperative that investing on proper asset control systems should become priority number one across organizations around the globe looking forward onwards becoming more competitive amidst growing competition landscapes worldwide while attempting ensuring higher degrees profitability performance over coming periods .

Key Components of Inventory Management

Inventory management is a necessary part of any business strategy. Companies need to take into account customer demand, manage inventory levels, and find the best balance between having too much or not enough stock in order to properly carry out their plan. A great way for businesses to achieve this is by employing forecasting methods that anticipate future needs as well as using safety stock (buffer stock) so they remain protected from changes in supply, manufacturing yields etc.

Using specialized tools dedicated towards managing inventory can be incredibly useful when it comes reducing costs associated with these efforts. Whilst also making sure adequate amounts are available at all times where required, an essential element of effective inventory control measures . To meet both short-term demands and long term objectives effectively. Those overseeing such operations must consider all aspects regarding maintaining proper stocking requirements across various platforms including online ordering systems.

Types of Inventory Management Systems

Inventory management is a critical process for businesses of all sizes. To make the most of their resources, they can implement various types of inventory management systems ranging from paper-based solutions to automated tracking technologies that provide live updates on stock levels.

No matter what system you choose, it will allow better oversight and control over inventories through improved data collection and accuracy in order processing tasks such as reordering items or understanding demand patterns. As an added bonus, these advances also optimize time efficiency by automating many aspects related to managing supplies across multiple locations

Manual Inventory Systems

Manual inventory systems, such as spreadsheets and paper-based tracking solutions or physical counting techniques, are low cost to use yet still provide flexibility. These methods can lead to inaccuracies due to potential errors by humans and an inability for real time monitoring when the business begins scaling up. Despite its drawbacks though a manual system is suitable for small companies with limited stock. It enables them track their inventories in an effective manner at a minimal expense compared with automated processes employed by large organizations.

Periodic Inventory Systems

Periodic inventory systems involve regularly taking physical counts of stock at the start and end of predetermined times, allowing for an accurate assessment on quantities in storage. This system provides businesses with greater control over their outlay associated to stocking supplies, as well as enabling them to monitor inventories closely and detect any discrepancies quickly. The advantages are that it is more precise when tracking down numbers and also helps keeps costs low. But there may be a downside: namely time taken in counting plus potential human error arising from this process. *** Note: for physical inventory, we recommend using digital parts counting scales to accomplish this task. See our how to guide for more info. This can speed up the physical count process and dramatically reduce the errors from hand counting.

Perpetual Inventory Systems

A perpetual inventory system is a computerized approach that automatically tracks and updates the number of products available at any given time. With technologies like barcodes and RFID tags, this type of inventory control ensures instantaneous monitoring and accuracy. Businesses can observe their current stock levels quickly, easily identify discrepancies, and adjust accordingly in real-time.

These systems offer immense benefit to firms with complex or high demands when it comes to tracking supplies since they eliminate manual work entirely while ensuring accurate records are kept continuously up-to-date.

Inventory Management Techniques

Inventory management is a key tool used to keep stock at optimal levels and reduce costs, helping many businesses stay afloat. Among the different techniques are Economic Order Quantity (EOQ), ABC Analysis, and Just-in-Time Inventory Management. All of these have potential advantages for your company if implemented correctly.

The EOQ system helps determine ordering cycles with regards to inventory needs in order maximize efficiency while also minimizing stock expenditure, on the other hand ABC analysis allows you classify items based upon their usage frequency within an organization so that prioritization can take place when managing stock levels accordingly, Lastly JIT represents a method wherein goods are sourced or acquired only as they are needed rather than ahead of time

Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a formula that helps businesses calculate the most cost-effective quantity of inventory to purchase, taking into account production costs, demand rate and other factors. By using EOQ for their inventory control strategy, companies can reduce both ordering expenses as well as holding charges associated with stocking up on products.

Since this equation does not take lead time (the amount of time it takes to order and receive new stock) into consideration it may result in stockouts (products being out of stock) due to extended delays between orders being placed and received by the company

ABC Analysis

ABC Analysis is a categorization system used to inventory items based on their value and usage. This approach enables firms to identify the most valuable products as well as efficiently manage resources for improved stock management and cost savings. Goods are separated into three classifications: Category A, B, or C with those in ‘A’ having highest worthiness. With this method, companies can prioritize high-value goods while improving inventory control which leads to reductions in costs incurred by the organization overall.

Just-in-Time (JIT) Inventory Management

Inventory management with a Just-in-Time approach reduces stock levels through the acquisition of goods only when necessary, cutting storage costs. This type of strategy is excellent for companies that are expanding their product lines and launching new products quickly. Apple has implemented JIT effectively in its supply chain operations resulting in cost savings and little surplus inventory.

With this process, keeping track of inventories by reducing stock helps maintain optimal balance between demand and available resources while minimizing risks associated with overstocking or under stocking items

Overcoming Inventory Management Challenges

To maintain successful operations, inventory data, and optimal customer satisfaction, businesses must be able to address inventory management challenges. These can include dealing with changing demand levels, controlling storage costs, and guaranteeing accurate stock assessment.

By utilizing suitable techniques and approaches organizations are equipped to take on these challenges effectively while improving their overall inventory management endeavors.

Managing Fluctuating Demand

Having the capacity to forecast and respond rapidly to shifts in customer demand is paramount for maintaining a consistent supply of goods. Effectively managing fluctuating demand involves forecasting precisely and having an inventory strategy like just-in-time or safety stock, which will ensure that businesses have ample amounts of items available while still upholding good cash flow.

Controlling Storage Costs

For a business to remain financially successful, it is necessary that the storage costs are managed adequately. Cutting down on warehousing space and eliminating too much stock can be highly beneficial for controlling expenses related to storage.

Adopting methods like grouping of items stored together in one area, categorizing data or using software-oriented storing technology will result in reduced expenditure linked with keeping records since they facilitate efficient management as well as retrieval of information without difficulty.

Ensuring Accurate Stock Counts

Accurate stock counts are essential for businesses to ensure that they have the appropriate level of inventory on hand in order to meet customer demand. Strategies which can be employed in ensuring accurate stock levels include conducting regular physical inventories using parts counting scales, reconciling inventory records, organizing warehouses properly and making use of technology such as RFID tags. Double-checking and auditing will help with accuracy while creating unique descriptions and locations for each individual item is also important within an effective system of inventory management. All these approaches taken together provide a comprehensive solution by helping companies manage their stocks more accurately, thus allowing them effectively satisfy consumer demands.

Implementing Inventory Management Software

When it comes to streamlining inventory tracking and control, businesses can reap huge benefits from implementing the right inventory management software. These platforms help them optimize their stock levels while cutting costs and improving customer service. There are some software choices available such as WeighVault or PLU Lite that integrate with certain counting scales.

Today, a variety of options are available for different business needs. What makes up a great solution in terms of features that would enhance your operations related to managing goods at warehouses -inventory/stock movement history & future forecasting, etc… How should you decide which one is best suited for you on financial grounds? One time payment vs. subscription fees vs. expected ROI growth over time using analytics about current sales patterns.

Benefits of Inventory Management Software

Using inventory management software provides numerous advantages such as improved real-time visibility, automated processes and heightened accuracy. Companies are able to keep track of their inventories in order to guarantee the necessary quantities on hand and make sound decisions based on this information. Automation simplifies the whole process, reducing manual labor while also preventing mistakes from occurring. Also, with increased precision levels businesses can maintain balanced stock at all times. A key factor for managing expenses related to incorrect ordering quantity (i.e., either over or under stocking) plus making sure customer deliveries happen punctually.

Choosing the Right Inventory Management Software

When searching for inventory management software, businesses need to evaluate features and compatibility as well as scalability in order to find the most suitable option. Thus it is important that thorough research of different options takes place. Key factors worth considering include how easy the system is use and integration with existing systems along with customer support levels provided before coming to a conclusion about which solution best suits your needs.

Industry-Specific Inventory Management

It is important for inventory management strategies and systems to be tailored to the particular challenges of any industry. Here we will discuss techniques specific for retail, manufacturing, and e-commerce industries that are used in inventory management.

The process must take into account individual needs so that it can properly address the unique characteristics associated with each sector. It is necessary to customize approaches accordingly in order maintain an effective system overall.

Retail Inventory Management

Retail inventory management aims to ensure customer satisfaction and maximize stock levels in stores. Companies like IKEA utilize cutting-edge methods of optimization for their supply chains, all while keeping a close watch on their inventories.

Various ecommerce outlets such as Amazon, Walmart and Shopify are used by retailers when it comes to managing the necessary resources that meet customer demand adequately.

Manufacturing Inventory Management

Inventory management in manufacturing involves keeping track of raw materials, WIP (work-in-progress), and the finished goods as they make their way through production. Inventory control tactics such as First In/First Out or JIT inventory methods can be used to maximize inventory levels while minimizing waste.

There are difficulties that come along with managing supply chain needs like varying demand, controlling storage costs effectively, and making sure accurate stock numbers are available for use within a company’s supply chain system..

E-Commerce Inventory Management

E-commerce inventory management involves overseeing multi-channel sales, order fulfillment and stock control from different sources. Businesses can use tools such as Shopify to effectively oversee their e-commerce inventories in a way that ensures customer satisfaction.

These types of multichannel inventory systems enable companies to track their levels of goods held by them, reorder products when necessary and project future demand for items on a quarterly basis. All which is crucial information used for proper planning related to an optimal rate at which the company’s merchandise will be converted into income throughout any given period.

Summary

Maintaining an effective inventory management system is critical for any business to succeed in today’s competitive environment. By being aware of its importance, utilizing various systems and techniques, surmounting difficulties and employing industry-specific tactics you can optimize your stock levels while cutting expenses. All this without jeopardizing customer satisfaction. Poor inventory control should not be an obstacle – make use of these important insights right now so that your enterprise blossoms.

Inventory Management System Frequently Asked Questions

What are some Simple Ways to Manage Inventory Inexpensively?

The following is a great inventory management plan. You can schedule your physical inventory to be done as often as you think is necessary. Many companies do this twice a year. When you set this up, just call your scale company and discuss how big your facility is and how many counting scales you need to rent. Sometimes companies just rent standard counting scales. Other times, companies rent a counting scale that is connected to a larger platform scale for counting really large amounts of product. All of this can be done without actually purchasing any of the weighing equipment. The rental usually lasts a week or two and then you’re done until next inventory.

What are the 4 types of inventory?

Inventory management is essential for successful businesses. To aid in this, there are four main inventory types which help to classify and keep track of items: Raw Materials, Work-in-Progress (WIP), Finished Goods, and Maintenance Repair & Overhaul (MRO). Knowing the differences between these different categories assists with more effective inventory control. With a better understanding of their various inventories, companies can benefit from smarter management strategies for all stock or potential future needs.

What are 5 stages of inventory management process?

Inventory management is a process made up of five stages: incoming goods are inspected and put in order, customer orders accepted, filled and shipped off. When necessary items are re-ordered to restock.

What are the 3 major inventory management techniques?

Inventory management techniques are utilized to balance and optimize stock supply, avoiding both overstocking or depleting inventories. There are three major strategies which serve this purpose: the push technique, the pull technique, as well as just-in-time approach, all helping businesses meet customer demand more efficiently. All these approaches form part of an overall inventory control system that seeks optimal solutions for keeping supplies in check so organizations can better satisfy consumer requests without being held back by excess stocks or shortages.

What is basic inventory management?

Inventory management is a practice that helps businesses to regulate the flow of their goods and materials. It involves keeping track of stock levels, from purchasing to selling, in order to guarantee customers’ orders can be satisfied according to trends.

What is the advantage of implementing a good inventory management system?

A good inventory management system can help businesses meet customer needs, prevent stock shortages and streamline operations for improved success. By having a well-run inventory control process in place, companies are better prepared to satisfy orders on time while also avoiding product oversupply issues.

For additional information on our lineup of counting scales and how they can help you better manage your parts inventory be sure to contact us (919) 776-7737 or you can complete the RFQ form on our website for more info on the products we recommend.