Looking to elevate your beer brewing with precise grain measurements? Grain weighing scales are pivotal to ensuring the consistency and quality of your brews. Whether you’re running a commercial brewery or home brewing, selecting the right scale will make all the difference. This article dives into the features and considerations necessary for picking the best grain scale to suit your needs.

-

Grain scales enhance brewing precision by ensuring accurate measurements of ingredients, which is crucial for maintaining consistent beer quality, taste, and alcohol content across batches.

-

The selection of the right grain scale involves considering factors such as the brewery’s size, weight capacity and durability needs, with features like stainless steel components, tare function, and IP66 rating or higher for cleanliness and ease of maintenance.

-

Advancements in grain weighing technology, like digital scales with high precision and integration capabilities, support brewing efficiency, consistency, and help in scaling production while minimizing human error and labor.

The Essential Role of Grain Scales in Brewing

The craft of brewing is akin to the delicate artistry of a symphony orchestra’s conductor, pivotal though often out of sight. In this intricate ensemble, scales designed for measuring grain function as virtuosos in ensuring exactitude within beer recipes. These instruments are vital for consistency, certifying that each new batch mirrors the exceptional taste and maintains the alcohol level anticipated by consumers—elements central to defining both character and standard.

In facilitating this meticulous process, digital scales have become transformative tools. They work by converting pressure applied on a load cell into an electrical signal which then manifests as an accurate digital display. This advancement permits unfailing measurement of every component—from grains to hops—fortifying each brew with uniformity in quality that enthusiasts have come to expect with every pour.

Precision Meets Practicality

In the beer brewing industry, precision in weight measurement trumps volume. This ensures that varying factors such as ingredient shape, density, and temperature do not compromise flavor or recipe exactitude. Grain scales step up to be the ideal solution here due to their many benefits.

-

They yield more precise measurements than those based on volume.

-

Their expansive plate comfortably supports grain containers.

-

The digital display remains visible for easy reading while blending functionality with accuracy.

The use of a grain scale can substantially refine your brewery operation and lead to consistent, flavorful outcomes.

These scales empower brewers with the capability to craft exceptional beers effortlessly. A straightforward dial allows them accurate weighing of grains so they’re prepared to concoct the perfect brew. Thanks to their ease of cleaning and stainless steel weighing surface, these scales seamlessly integrate into any brewery’s setup, whether it aims high volumes or operates at a modest scale.

The Tare Function Advantage

The tare function on scales provides many benefits, especially for brewers who require precise and immediate weighing during the brewing process. This handy feature allows for the container’s weight to be subtracted so that only the net weight of the grain or other ingredients is measured. Such accuracy is essential not just for crafting original recipes, but also when making incremental additions or modifications.

Grain scales equipped with a tare function greatly streamline production by allowing bulk materials to be weighed without including the weight of their containers in measurements. Effectively acting as an invisible helper, this function ensures simplicity throughout brewing operations while guaranteeing that ingredient measurements are both accurate and focused solely on their actual weights.

Selecting the Right Grain Scale for Your Brewery

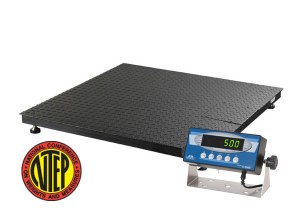

Choosing an ideal grain scale is as crucial as selecting the finest specialty grains for your brewing process. The chosen scale needs to be in sync with the production scope and size of your brewery. Smaller operations like home or microbreweries may opt for precision balances tailored to minor ingredients, alongside bench or floor scales suited for heftier batches. Meanwhile, larger-scale breweries typically require robust platform scales or tank scale load cells that accommodate extensive batch sizes and fulfill shipping demands.

It’s vital to pay close attention to the capacity of the grain scale, ensuring it prevents inefficiencies and inaccuracies which can occur when measuring large batches in smaller increments. For those brewers who mill their own grains, a grain scale with around 400 pounds capacity becomes indispensable during this phase of processing. Valuable are features such as extendable displays that simplify visibility throughout use – these enhancements play a significant role in facilitating an easy and efficient brew-making experience.

Match Your Batch: Weighing Capacity Considerations

The production scale of a brewery dictates the necessary weight range for its scales. Accurate weighing is critical, regardless of whether it’s small-scale batches or large-scale brewing operations. Scales with the ability to measure in pounds and equipped with sufficient capacity are vital to ensure precise measurements of grains as per the recipes utilized by the brewery.

In cases where scales come with smaller platforms, options exist to either acquire larger platform scales or enhance them through different means such as installing plywood or flat steel extensions. This adaptability ensures that your brewing scale can grow in tandem with the evolution of your brewery’s needs.

Durability for the Brew Day: Build Quality and Materials

When choosing a grain scale for brew day, it’s important to consider its robustness and longevity. Look for scales with features such as:

-

Resistance to corrosion

-

Ability to retain durability at elevated temperatures

-

Effectiveness in very low temperature conditions

-

Design that enhances the appearance of a clean, professional brewery setting

-

Prevention of bacterial development

For the rigorous cleaning processes common in brewery environments, opt for scales rated IP66 or higher. This rating indicates they can withstand regular washdowns without compromising their lifespan. Scales constructed with sanitary considerations in mind are crucial. This includes heavy-duty strain gauge load cells which provide both accurate measurements and the ability to support large loads from hefty kegs and bulk grain deliveries.

Precision Balances for Specialty Grains

Precision balances are vital tools in the brewing process, especially when dealing with specialty grains. They act as a critical element for obtaining exact measurements, and even minor deviations in grain quantities can have a profound effect on beer flavor. For breweries that craft an array of seasonal or experimental beers, it is imperative to employ precision scales capable of measuring small amounts of diverse ingredients accurately.

For components such as hops and brewing salts where accuracy down to the gram is paramount, scales offering greater precision take precedence over those designed for larger weight capacities. The stainless steel digital scale stands out due to its precise readings and extended battery life. These attributes make it ideal for measuring not only hops, but also minerals and brewing salts. Precision balances equipped with features tailored for formulation help breweries seamlessly navigate through various recipes—this aids immensely in maintaining both quality and uniformity across their range of beer products.

Achieving Flavor Accuracy

Precision in measuring specialty grains is crucial for retaining the distinctiveness and intricacy of beer flavors, as it ensures flavor accuracy. Accurate scales are essential tools for brewers to replicate particular beer recipes reliably or adjust them to refine or amend their taste profiles.

When working with ingredients such as specialty grains that greatly influence a beer’s flavor, using a digital brewing scale yields more precise measurements than volume-based approaches. Stainless steel digital scales come highly recommended due to their exactness and robustness, making them perfect for weighing smaller amounts of items like hops and brewing salts.

Enhancing Brewery Efficiency with the Right Equipment

Utilizing robust and accurate scales for weighing is vital in boosting the efficiency of a brewery and ensuring that each batch of beer produced maintains consistent quality. Accuracy in scales ensures that every bottle of beer retains uniform taste and alcohol levels, which contributes to a profitable brewing operation.

Having precise measuring tools allows for the careful control of ingredient amounts, minimizing waste while adhering to ideal proportions – this is essential across all sizes of production batches. Brewers greatly benefit from heavy duty digital scales recognized for their large capacity and dependability when it comes time to weigh substantial quantities of grain, underlining the necessity for equipment scaled to meet production needs.

For breweries aiming at refining their brewing processes, integrating kg unit-measured grain scales as part of analytical assessments can significantly enhance both product consistency and overall process efficiency. These measurements play an integral role in tailoring brewing techniques towards optimized performance within the industry.

From Grain to Glass: Integrated Systems

In the beer industry, the combination of automation and weighing scales into cohesive systems is revolutionizing the process. These integrated systems enhance precision while reducing the need for manual oversight, which boosts both efficiency and profitability within breweries. The incorporation of these systems minimizes human error by enabling precise adjustments to adhere strictly to brewing requirements.

Scales that are integrated with ingredient databases can manage equipment like hoppers autonomously, stopping material flow when target weights are achieved. This optimizes the entire beer production procedure. By adopting such advanced equipment that ensures exact temperature control and automates water and malt delivery processes, microbreweries can achieve consistent replication of specific conditions—crucial for maintaining a uniform taste and high-quality standard in their brews.

Innovations in Grain Weighing Technology

The technological transformation of the brewing industry is spearheaded by advancements in grain weighing technology, which brings several advantages.

-

Scales that have the capability to automate operations within expansive breweries by directing other equipment such as hoppers reduce manual intervention.

-

There’s a decrease in inaccuracies caused by humans.

-

The precision of the brewing process sees significant improvement.

Advances linked to agriculture within the Internet of Things (IoT) realm have resulted in more cost-effective sensors and foster low-power network development. These innovations are instrumental for broad-scale deployment of interconnected grain weighing systems.

The Future is Digital: Technological Features

Grain scales that are digital represent a significant advancement in the brewing industry. Utilizing a load cell to detect the force placed upon it by an object, these scales transform this information into precise weight readings—a process essential for brewers seeking exact measurements for their grain.

The modern iterations of these scales come packed with convenient features like:

-

The capacity to transfer data instantly

-

Broad bandwidth capabilities

-

Accommodation for numerous devices simultaneously

-

Simplified calibration processes

-

An invaluable tare function

-

Illuminated display screens

-

An automatic shutoff mechanism designed to preserve battery power

Adapting with times, these scales now boast remote power supply systems and are embracing cutting-edge connectivity options, thereby enhancing both efficiency and ease-of-use.

Grain Scales Across the Industry: Top Brands and Models

In the brewing industry, leading brands and models of grain scales are crucial for preserving consistent quality and precision throughout the beer production process.

The Brewer’s Pick: Customer Reviews

Brewers and their clientele place a high importance on certain characteristics of grain scales, such as:

-

The precision and dependability of the scales

-

Consistency in measurements to ensure the same quality in each batch of beer

-

User-friendliness

-

Robustness

Owing to these attributes, grain scales are highly favored by brewers.

Digital weighing equipment designed for brewing comes equipped with several advantageous properties that include:

-

Display clarity under varying light conditions

-

A tare function allowing for effortless net measurement without being misled by the weight of the container

-

Enhanced accuracy essential when dealing with specialty grains which can significantly alter beer’s taste profile

Such features improve traditional methods and are regarded by brewers as critical components within their arsenal of brewing gear.

On another note, particular customers emphasize how crucial it is for these instruments to have an ample range in terms of scale capacity. This ensures adaptability across various sizes required during different stages or styles of producing grain-based alcoholic beverages.

A Guide to Maintaining Your Grain Scale

The upkeep of your grain scale is as vital to the brewing process as making the beer itself. To ensure ongoing accuracy, it’s essential that you recalibrate the scale periodically to avoid any deviations in measurement that may occur over time. When cleaning, opt for gentle methods like a soft brush or compressed air to clear away leftover grains and dust without compromising the precision of your measurements. Avoid using harsh chemicals or rough cleaning tools which can harm the delicate parts of your grain scale.

For those who need scales capable of withstanding rigorous hygiene standards, select washdown scales carrying a minimum IP66 rating for their resistance against water intrusion. This makes them easier to clean while staying compliant with health regulations. Consistent cleanliness helps prevent residue accumulation, which might interfere with measurement reliability. Ensure long-term functionality and durability by storing your grain scale in an area shielded from excessive moisture and drastic temperature changes.

Calibration for Consistency

Ensuring that your grain scale is calibrated regularly is essential for precise measurements. The selection of an appropriate test weight during calibration plays a vital role, and it’s best to choose one that approximates the most common weight measured by the scale. For optimal calibration results, use a test weight that ranges from 50% up to the full capacity of the grain scale.

Employing low-quality, imprecise weights for calibration can lead to erroneous readings. Once professionally calibrated at the factory, it’s important to schedule subsequent calibrations with a trusted scale service provider in order to preserve measurement accuracy. After calibrating your grain scale, confirm its precision by using a known weight. This ensures both accurate measurement display and proper zero resetting functionality on the device. To maintain consistent accuracy over time, establish regular intervals for re-calibration based upon usage frequency and adhere strictly to guidelines provided by the manufacturer.

Building Your New Brewery: Incorporating the Perfect Grain Scale

When embarking on the creation of a new brewery, it’s essential to integrate an ideal grain scale into the brewing process. The adoption of micro brewing systems offers a budget-friendly alternative for nascent breweries, circumventing the high costs tied to large-scale equipment.

By buying ingredients wholesale and eliminating the necessity to lease equipment or purchase ready-made beer, these new breweries stand to reap considerable cost reductions over time.

Designing with Precision in Mind

In the process of crafting your new brewery, accuracy is a crucial element to consider. Ensuring that the selected grain scale can accurately gauge the common quantities of grains required by your brewing recipes is essential for maintaining both precision and consistency in your final brews.

Your brewery’s design should integrate a grain scale with features that allow:

-

Continuous and immediate monitoring of grain weight.

-

Sustained dependability and uniformity within the brewing processes.

-

An improvement in the efficiency of how work flows throughout the brewery.

In conclusion, the role of grain scales in brewing cannot be overstated. They are really the silent heroes behind each brew, ensuring precision, consistency, and efficiency in brewing operations. From choosing the right scale(s) for your brewery, understanding the importance of precision balances for specialty grains, to maintaining your scale, each step plays a significant role in crafting the perfect brew. The innovations in grain weighing technology and the digital future of brewing only underscore the importance of grain scales in this process. Every brewer’s journey, from grain to glass, is a testament to the power of precision, and the grain scale is your trusted companion on this journey.

Frequently Asked Questions

What SCALES ARE NEEDED AT A brewery?

This could vary between breweries, but it’s usually a good idea to place load cells under the tank legs. It’s usually helpful to have some type of bench scales with around a 500 lb capacity. It’s good to have some lab balances for quality control. Finally, it’s good to have some material handling scales for your warehouse such as 5’x5′ floor scales with ramp and possibly a pallet truck scale.

Why is precision important in brewing?

Consistency in flavor, alcohol levels, and the ability to replicate and tweak a brewing recipe easily are all ensured by precise measurements during the process. This also helps reduce waste.

Why is measuring by weight preferred over volume in brewing?

In brewing, the use of weight measurements is favored over volume due to its higher level of precision. This consideration takes into account various factors such as the shape, density, and temperature of ingredients, which enhances both the flavor and exactness of a recipe.

If you need assistance choosing your scales and weighing equipment, be sure to contact our customer service department. We also offer scale repairs and calibration service as well for central North Carolina customers.