Looking to elevate your beer brewing with precise grain measurements? Grain weighing scales are pivotal to ensuring the consistency and quality of your brews. Whether you’re running a commercial brewery or home brewing, selecting the right scale will make all the difference. This article dives into the features and considerations necessary for picking the best grain scale to suit your needs.

-

Grain scales enhance brewing precision by ensuring accurate measurements of ingredients, which is crucial for maintaining consistent beer quality, taste, and alcohol content across batches.

-

The selection of the right grain scale involves considering factors such as the brewery’s size, weight capacity and durability needs, with features like stainless steel components, tare function, and IP66 rating or higher for cleanliness and ease of maintenance.

-

Advancements in grain weighing technology, like digital scales with high precision and integration capabilities, support brewing efficiency, consistency, and help in scaling production while minimizing human error and labor.

The Essential Role of Grain Scales in Brewing

The craft of brewing is akin to the delicate artistry of a symphony orchestra’s conductor, pivotal though often out of sight. In this intricate ensemble, scales designed for measuring grain function as virtuosos in ensuring exactitude within beer recipes. These instruments are vital for consistency, certifying that each new batch mirrors the exceptional taste and maintains the alcohol level anticipated by consumers—elements central to defining both character and standard.

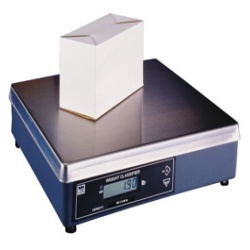

In facilitating this meticulous process, digital scales have become transformative tools. They work by converting pressure applied on a load cell into an electrical signal which then manifests as an accurate digital display. This advancement permits unfailing measurement of every component—from grains to hops—fortifying each brew with uniformity in quality that enthusiasts have come to expect with every pour.

Precision Meets Practicality

In the beer brewing industry, precision in weight measurement trumps volume. This ensures that varying factors such as ingredient shape, density, and temperature do not compromise flavor or recipe exactitude. Grain scales step up to be the ideal solution here due to their many benefits.

-

They yield more precise measurements than those based on volume.

-

Their expansive plate comfortably supports grain containers.

-

The digital display remains visible for easy reading while blending functionality with accuracy.

The use of a grain scale can substantially refine your brewery operation and lead to consistent, flavorful outcomes.

These scales empower brewers with the capability to craft exceptional beers effortlessly. A straightforward dial allows them accurate weighing of grains so they’re prepared to concoct the perfect brew. Thanks to their ease of cleaning and stainless steel weighing surface, these scales seamlessly integrate into any brewery’s setup, whether it aims high volumes or operates at a modest scale.

The Tare Function Advantage

The tare function on scales provides many benefits, especially for brewers who require precise and immediate weighing during the brewing process. This handy feature allows for the container’s weight to be subtracted so that only the net weight of the grain or other ingredients is measured. Such accuracy is essential not just for crafting original recipes, but also when making incremental additions or modifications.

Grain scales equipped with a tare function greatly streamline production by allowing bulk materials to be weighed without including the weight of their containers in measurements. Effectively acting as an invisible helper, this function ensures simplicity throughout brewing operations while guaranteeing that ingredient measurements are both accurate and focused solely on their actual weights.

Selecting the Right Grain Scale for Your Brewery

Choosing an ideal grain scale is as crucial as selecting the finest specialty grains for your brewing process. The chosen scale needs to be in sync with the production scope and size of your brewery. Smaller operations like home or microbreweries may opt for precision balances tailored to minor ingredients, alongside bench or floor scales suited for heftier batches. Meanwhile, larger-scale breweries typically require robust platform scales or tank scale load cells that accommodate extensive batch sizes and fulfill shipping demands. Continue reading

Our

Our