Grain testing scales are essential tools used in agricultural sampling houses for coops, large farms, and the food processing industry to determine the quality and value of grain. Here’s a step-by-step explanation of their use and requirements for legal-for-trade classification:

Sample Collection

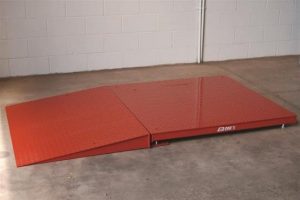

Grain samples are typically collected by a probe while the grain is loaded in a truck and being weighed on a static truck scale. Proper sampling is crucial to ensure the sample is representative of the entire batch, so the probe will typically select the sampling from random spots within the batch.

Weighing

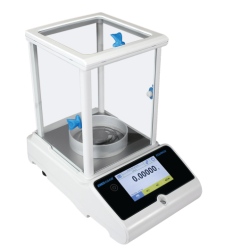

The grain sample is brought into the scale house via the probe. There the sample is placed on a testing scale to measure its weight. This measurement helps in determining the test weight of the grain, which is a key factor in marketing and pricing. Test weight indicates the density of the grain and can influence its market value.

Grain scales such as Cardinal Detecto models 420-3000, 420-1200, and 420-600 provide quick and accurate weight measurements for a variety of grains. These small countertop scales are typically situated next to the grain moisture meter in the scale house.

Moisture Testing

After the sample has been weighed, it is then tested for moisture content using a grain moisture meter. This step is essential for assessing the grain’s quality and suitability for storage and processing.

Dockage Testing

Dockage testing helps separate impurities from the grain. Dockage is foreign material typically not included in the market price.

Data Recording

The weights and measurements obtained from the scale and grain moisture meter are recorded and analyzed. These data points provide insights into the quality, purity, and potential yield of the grain batch.

Quality Grading

Based on the weight and size distribution, the grain is graded. Higher test weights generally indicate better grain quality, which fetches higher prices on the market. These procedures ensure that the grain meets industry standards and helps in making informed decisions regarding its sales and processing.

Detecto model 420-3000 class II legal-for-trade scale is a popular choice for grain testing weighing due to its 60,000-division resolution combined with a price point nearly $1000 less than any other competitor’s NTEP scales in that resolution category. Multiple other 420 series models with varying capacities and similar price range are also available in the 60,000-division category, making them NTEP (National Type Evaluation Program) legal-for-trade for grain sampling weighing applications. They only take up 8.6 inch x 11.5 inch of counter space and come with an AC adapter and rechargeable battery.

The 420-3000 sampling scale has a 7.4 inch by 5.8 inch stainless steel platform that can be lifted off for easy cleaning after grain weighing. The precision digital balance scale has a 3,000 gram capacity with 0.05 gram divisions, conforming to NTEP class II Handbook 44 requirements, for use in both commercial and GIPSA (Grain Inspection, Packers, and Stockyards Administration) applications.

The scale division for grain testing scales, according to Handbook 44, must not exceed 0.2 grams for loads through 500 grams, and must not exceed 1 gram for loads above 500 grams through 1,000 grams, so the 420-3000 is well below those requirements at only 0.05 gram divisions.

One of the factors in grain quality that sampling houses will be looking for is dockage, such as debris and hulls. Dockage refers to the foreign material and impurities, such as fungus, in grain that needs to be removed to assess its true quality and value.

Scale house operators will test for fungus by weighing good grain samples first and weighing grain samples with fungus present afterward to extrapolate from the total load and subtract the dollar amount from the load’s value. These minute weight differences between dockage and live weight samples are why grain test scales with tight division values are critical in the process.

The grain samples are subjected to dockage testing using specialized equipment like dockage testers. These testers help in separating the impurities from the grain, providing a clear measurement of the dockage percentage.

Dockage testing is a critical step in the grain grading process, ensuring that only high-quality, impurity-free grain reaches the market, which benefits both producers and consumers. The grain elevator purchasing company discloses dockage prior to the transaction being completed, so the farmer can accept the offer or decline it and check if they can get a better dockage elsewhere, and therefore a better price, from another buyer.

The USDA’s Grain Inspection, Packers, and Stockyards Administration, otherwise known as GIPSA, establishes regulations for grain weighing under the United States Grain Standards Act (USGSA).

These regulations ensure accurate and fair grain weighing practices, which are critical for maintaining market integrity. GIPSA sets official performance and procedural requirements for grain weighing equipment. This includes the guidelines for accuracy, calibration, and maintenance of weighing devices used in grain handling facilities.

Sampling houses in commercial applications must use grain testing scales that are NTEP approved and placed in service legal for trade. Depending upon the state, the scales would be placed in service by a state scale inspector or a registered scale service agency. Most states will not place a scale in service that does not have NTEP certificate or conformance, but in the end that is determined by the state.

The owner of the scale is responsible for the scale, so if it is either not suitable or out of tolerance, the owner is liable and could face fines, which are generally levied by the state attorney office. Detecto 420 series scales combine NTEP legal-for-trade class II status that conforms to Handbook 44 and USDA GIPSA requirements, in the division size necessary, with a much lower price point than any other competitors’ scales on the market making them a clear choice for grain testing weighing.

Contact our sales department today to learn more about the 420 series.