We sell & repair scales and weighing equipment.

One of the first items to consider is the environment where the weighing apparatus will be used.

|

What will the load cells be exposed to in their normal operational function? |

|

|

? |

Will the cell be exposed to dry, wet or airborne chemicals? |

|

? |

If chemicals are present, what are they? |

|

? |

Will the cell be exposed to washdown cleaning, humid or occasional submersion conditions? |

If the answer is yes to any of these questions, further investigation needs to be done.

|

Tool

Steel

|

|

Aluminum

|

|

Stainless

Steel

|

Tool steel elements are by far the most popular load cells used today. The cost-to-performance ratio is better, compared to other materials used in load cell construction. The most popular alloy used is 4330. Tool steel load cells are relatively inexpensive, have a large capacity range and are best used in dry applications.

Aluminum is primarily used in single point, low capacity applications. The aluminum of choice is 2023 because of low creep and hysteresis. Aluminum is the least expensive of the three materials used to manufacture load cells. Aluminum load cells are limited by their low capacity range and should not be exposed to wet or chemical conditions.

The third material used for load cell manufacturing is stainless steel. The stainless alloy used is 17-4 ph. This alloy has the best overall performance of any of the stainless derivatives. Stainless steel load cells are more expensive than tool steel or aluminum, but their resistance to corrosion makes them an ideal choice in wet or corrosive applications.

Sealing Techniques

Another important item to consider when designing a weighing system is how the load cell’s internal components are protected from the environment.

“Environmentally sealed” is used to describe several techniques, but ultimately is accomplished by one or more of the following: Rubber “boots”, glued on covers or potting the gauge cavity of the load cell. This type of sealing will protect the load cell from damage caused by dust and debris and moderate humidity caused by splashing of water. In no way will the load cell be protected from immersion under water or being exposed to pressure cleaning.

Another sealing technique used on load cells is “hermetically sealed.” This incorporates a welded cover or sleeve that encapsulates the gauge pocket. The cable entry area also uses a welded barrier to prevent moisture from “wicking” into the load cell, and shorting it out. This technique is generally used with stainless steel load cells as a stainless, hermetically sealed load cell should only be used in heavy wash down or chemical applications. This makes for a more expensive load cell but if long life in a hostile environment is desired, this is the most cost effective solution in the long run.

A “welded sealed” load cell is identical to a hermetically sealed cell, with the exception of where the load cell cable comes out. A welded sealed cell typically has the same load cell cable attachment as the environmentally sealed cell. In some instances, the welded sealed cell may have a conduit adapter for the load cell cable, affording some level of protection. While the gauge area itself is protected by the welded seal, the cable entry is not. Welded sealed load cells are for use where the cell may get wet on occasion, but are not intended for heavy wash down applications.

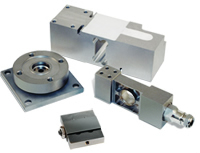

Types of Load Cells

S-beam load cell are typically used when hanging or suspending a weighing system (used in tension). Every now and then somebody will refer to these as z beam load cells. Since only half of this cell is live while the other half is inert, it is important to ensure that it is properly positioned. A simple way to distinguish the top from the bottom of the cell is to look at which side the cable protrudes. This side is inert and should be placed in the upward position to avoid any weight discrepancies associated with the cable.

Shear beam load cells are manufactured in capacities of 1,000 pounds and higher. These load cells have an actual “shear” machined inside to protect the cell from side loading forces.

Bending

beam load cells are typically found in bench scales and are of

lighter capacity.

Canister load cells were the first type of strain gauge load cell.

All other types of strain gauge load cells have evolved over the years

from that original canister design.

Today, canister type load cells are used for weighing systems in excess of 200,000 pounds per cell. That being said, today there are double-ended shear beam load cells that are available in capacities up to 200,000 pounds as well. Using a double-ended shear beam in a load cell mount eliminates the need for checking, thus eliminating added cost associated with a canister cell used in the same application. Most canister load cells are sold as replacement cells for older systems.

It is important to know what the resolution of the weighing system is in order to select the right capacity cells while attaining the desired sensitivity (readability). Simply stated, resolution equals scale system capacity divided by sensitivity. For example, a 5,000 pound floor scale reads in 1 pound increments and has a stated resolution of 1:5,000 (5,000 pounds divided by 1 pound). If that same 5,000 pound system needed to display the weight in .5 pound increments, the scale’s resolution would change to 1:10,000 (5,000 divided by .5). This is important because as the resolution gets higher, the actual millivolt output per division gets smaller. The smaller each millivolt reading, the more difficult it is to detect small changes in weight. A scale system with a resolution of 1:5,000 would have a .006 mV per division change (30 mv divided by 5,000 divisions). That same system with a resolution of 1:10,000 would have a .003 mV per division change.

The number of load cells used in a weighing system also needs to be considered. When designing a weigh hopper system, it is preferable to use a three load cell system rather than four or more load cells. This is because a three cell system has the weight perfectly distributed on each load cell. When using four or more cells, it is vital to ensure that all cells are on the exact same plane in order to properly weigh. Portions of this courtesy of Paul Menge, Loadcell Product Mgr at Rice Lake Weighing