Veterinary clinics and Animal hospitals throughout the triangle area of North Carolina count on Central Carolina Scale to check and calibrate their vet scales on a regular basis. Our state certified scale technicians use certified calibration weights which are ideal weights to use when calibrating animal scales. They ensure your scale is properly calibrated and ready for the requirements of weighing in a wide range of animal care settings.

Weights for Animal Scale Calibration

Consumer weights such as barbells or similar items may not provide an accurate weight to calibrate your scale. For example, a 5-pound consumer weight, such as a barbell, may actually weigh between 4.75 and 5.25 pounds. Compare that to our certified calibration weights which have a manufactured and adjusted tolerance of +/-230 milligrams! Our scale tech’s use a certified calibration weight to ensure your scale is calibrated correctly and presents accurate weighments for proper animal care.

Our scale technicians use certified calibration weights ensure the scale is properly calibrated and ready to weigh a wide range of animal needs.

Animal patients can be unpredictable, especially if they are nervous or anxious at veterinary clinics. You may want to look for scales that have a low profile so animals aren’t taking large steps on or off the scale. Some scales may have optional mats to increase animal comfort as they step onto the weighing platform. The scales you use should also be durable and easy to clean. Hard, nonporous ABS plastic surfaces provide an easy-to-clean weighing platform that can withstand claws and accidents.

Functions such as weight recall, tare and movement compensation technology allow operators to record and verify accurate weights for every patient. Movement compensation technology in scales recognizes when a patient is moving or shaking on the weighing platform and accounts for that movement in the final weight display. You may want to consider these scale functions as well as automatic shut-off for long battery life as you search for a scale to meet the needs of your specific practice.

Standardizing the units of measure at your clinic and using scales that allow you to lock the units of measure can help you prevent potentially fatal errors. Some animal scales are able to lock units of measure, meaning the scale won’t accidentally be switched from pounds to kilograms, or vice versa. If a scale is unknowingly changed from kilograms to pounds, medication can be given in dangerously high amounts.

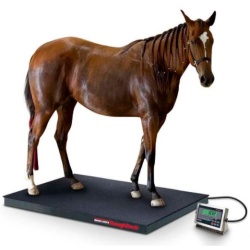

Recently we announced the availability of the new Rice Lake RoughDeck® EQ equine scale. Durability and repeatability are additional factors that should be considered when choosing large animal scales. A weighing system may be accurate when initially installed but fall out of tolerance as it is used. After all, horses are not always well-behaved during the weighing process—especially when they are not feeling well.

Selecting a scale that can handle reluctant patients’ antics, including hoof stomps, and still deliver consistent, stable weights is key for long-term use. Hermetically sealed load cells are ideal so the system can be washed down without damage. Regular inspections and calibrations should also be performed by a local, authorized scale service technician.

For more information on our cattle scales and related animal weighing products or scale calibration services, please call us at (919) 776-7737.