In a world where environmental consciousness is becoming increasingly critical, recycling stands out as one of the most effective tools in our arsenal to combat the escalating challenges of waste management and resource depletion.

Recycling not only helps conserve natural resources but also has far-reaching benefits for our society, economy, and the environment. This article explores the multifaceted advantages of recycling and highlights the pivotal role that scales play in this process, weighing collected materials and enabling efficient transportation for a more sustainable future.

-

Resource Conservation

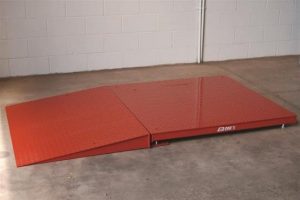

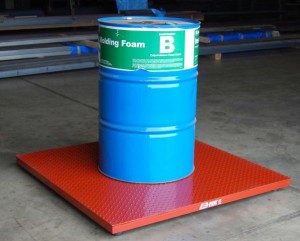

One of the primary benefits of recycling is resource conservation. By reusing and repurposing materials, we can reduce our dependence on virgin resources. Many valuable resources, such as metals, plastics, and paper, can be recycled multiple times, lessening the need for extensive mining, drilling, and deforestation. Scales play a crucial role in recycling by accurately weighing the collected materials either on a floor scale or a truck scale. By knowing the precise weight, industries can better manage their resources, plan for production, and contribute to a circular economy.

-

Energy Savings

Recycling offers substantial energy savings compared to extracting raw materials. The energy required to process recycled materials is significantly lower than that needed to produce products from scratch. For example, recycling aluminum consumes only about 5% of the energy required for primary production. By using scales to monitor incoming materials and outgoing products, recycling facilities can optimize their energy consumption and identify areas for further efficiency improvements.

-

Waste Reduction and Landfill Diversion

As the global population grows, so does the waste generated. Recycling helps divert a substantial amount of waste from landfills, reducing the burden on these sites and mitigating the associated environmental and health risks. By efficiently weighing the collected materials, municipalities can measure their recycling success, set targets for waste diversion, and develop waste management strategies that promote recycling and resource recovery.

-

Greenhouse Gas Emission Reduction

Recycling plays a pivotal role in reducing greenhouse gas emissions. When materials are discarded in landfills, they undergo anaerobic decomposition, releasing methane, a potent greenhouse gas. By recycling materials instead, we can significantly decrease methane emissions and contribute to mitigating climate change.

-

Job Creation and Economic Growth

Recycling creates a multitude of job opportunities across various sectors, from collection and sorting to processing and manufacturing. The recycling industry not only fosters local employment but also contributes to economic growth. Moreover, by reducing waste management costs and conserving resources, recycling can lead to cost savings for industries, promoting competitiveness and overall economic resilience.

-

Promoting Sustainable Consumption

Recycling is not solely a responsibility of waste management facilities. It also plays a crucial role in promoting sustainable consumption patterns. As people become more aware of the importance of recycling, they are encouraged to make eco-conscious choices, such as opting for products with recyclable packaging.

-

Preserving Biodiversity

By reducing the demand for raw materials and minimizing waste disposal in landfills, recycling helps preserve natural habitats and protect biodiversity. Deforestation for resource extraction and landfill expansion can have devastating effects on ecosystems.

-

Community Engagement and Environmental Education

Recycling initiatives often foster community engagement and environmental education. As people participate in recycling programs, they become more connected to sustainable practices and take pride in their efforts to protect the environment.

Recycling is a powerful mechanism that benefits society in multifaceted ways. It conserves resources, reduces energy consumption, diverts waste from landfills, curbs greenhouse gas emissions, stimulates economic growth, and preserves biodiversity. Scales play a vital role in weighing collected materials, usually on either a floor scale or a truck scale. By embracing recycling as a collective responsibility, we can create a more sustainable world for generations to come, where environmental consciousness and social well-being coexist in harmony.