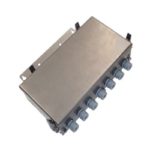

Back in September 2010, Thurman Scale originally released the Digital Smart Sectional Controller (DSSC) for converting Mettler® DigiTOL® scales to Intalogix. In July of 2018, the DSSC went End of Life (EoL) due to several electronic components used in the design no longer being available.

However, recently Thurman has been able to source components to allow them to again manufacture and offer the DSSC for customers who desire to convert their Mettler scale to Intalogix. Please continue reading as we discuss what the DSSC is all about and how it can help out a lot of customers who have older MT truck scales.

What is a Digital Smart Sectional Controller?

This is a special type of Smart Sectional Controller manufactured by Thurman Scale in St Johnsbury, Vermont specifically designed to interface to the Mettler 760 Powercell and MTX cells. These cells will have the cable connector on the top half and usually an orange label on the top half.

How do the DSSCs work?

The DSSC is very similar to the SSCs you may have heard of. DSSCs feature Thurman Scale Intalogix Technology. The DSSCs wire up very similar to the standard SSCs. Besides the ability to interface with the Mettler 760 Powercell and MTX cells, the DSSCs will drive four (4) load cells each, whereas the SSCs drive two (2) each. The DSSC was specifically designed to be a drop-in replacement for the existing Mettler junction box. The DSSCs even use the exiting Mettler mounting hardware. The DSSCs also use the same Pit Power Supplies as the standard SSCs.

Do the DSSCs only work with the Mettler 760 Powercell and MTX cells digital cells?

No. One of the best features of the DSSC is the ability to mix and match load cells.

As the Mettler 760 Powercell and MTX cells eventually fail, you can replace them with the standard analog 7.5” tall RC load cell (part # 95544 with 26’ cable). Other cable lengths available.

What scale instrumentation does the DSSC require?

The DSSC work with all Thurman Scale’s Heavy Capacity instruments which use Intalogix Technology. Such as TS611, TS612, & TS613.

Is special software required in the scale instrument to work with the DSSCs?

No special software is required to work with the DSSCs. Just 100% standard catalog products. From the instrument side, everything is exactly the same. You lose no instrument features or functions. You still have the very best load cell diagnostics available through Intalogix technology. You still have digitally isolated load cells. You still have optically isolated load cells. You still have the digital front panel calibration. Those items all remain intact because it is the exact same instrument. Simply choose the instrument that provides the best solution for you.

We also have an analog load cell scale kit replacement as well. However, in most cases we would probably recommend going with the Thurman digital scale equipment versus the older analog style load cells.

Is there a cumbersome load cell addressing scheme like some Mettler instruments require?

No. Just like any Intalogix system using our standard SSC, the cells are automatically

found and addressed by the DSSC ID. No connecting, disconnecting and reconnecting cells to find cell addresses.

Is this a new product?

No. The DSSCs were originally introduced by Thurman Scale in September 2010.

Have we done many conversions?

Completed conversions number over five hundred (500+) scales. This is a hardened, field-tested in the most demanding of all applications.

Will the DSSC work with the Mettler PDX digital cells?

No. The DSSC was designed specifically for the Mettler 760 Powercell and MTX cells. The Mettler PDX cell is a different digital load cell with a different digital interface compared to the Mettler 760 Powercell and MTX cells.

Will the DSSC work with the Cardinal digital cells or the B-Tek digital cells?

No to both the Cardinal & B-Tek. The DSSC was designed specifically for the Mettler 760 Powercell and MTX cells. The Cardinal digital system uses its own unique digital load cell with a unique and different digital interface compared to the Mettler 760 Powercell and MTX cells. Likewise, the B-Tek digital system uses its own unique digital load cell with a unique and different digital interface compared to the Mettler 760 Powercell and MTX cells.

So, why would someone want to buy this Thurman DSSC solution?

Mettler has updated their digital cells a few times over the years. Their current PDX load cell is not backward compatible with older digital cells. Mettler no longer manufacturers the 760 Powercell and MTX cells. This means if a customer has an older cell that fails, the MT solution is to replace every cell in the system to upgrade to the PDX cell.

Additionally, Mettler is no longer manufacturing instruments and replacement parts compatible with the Mettler 760 Powercell and MTX cells. This means the customer could face replacement of all load cells and the instrumentation. As you can imagine, this is not a desirable solution for most customers.

Until now, the owner of a Mettler Toledo truck scale using the Mettler 760 Powercell or MTX cells had no options but to replace all their load cells and possibly the instrument as well. No other manufacturer offers a similar solution to the DSSC. This is a unique product offering from Thurman Scale.

If this sounds like a product that would interest you, please complete our RFQ form on our website for more information.