Today, we’re going to talk about the advantages of buying a pallet scale with a ramp vs. installing a pallet scale into your concrete floor.

Maybe you would like a more portable floor scale that sits above ground with a ramp beside it. Or perhaps you would rather just have an in ground style floor scale and not have to deal with ramps.

We’re going to look at the advantages and disadvantages of both types of industrial scales, while helping you make a more informed buying decision.

A floor scale is a type of scale that can be used directly on the warehouse floor. A typical floor scale usually has a 4 inch height and the vast majority of platform scales are usually 4×4 or 5×5 dimensions. Great for weighing most pallets and in many situations, your scale company can ship your floor scales direct to you, either from the scale company or the scale manufacturer.

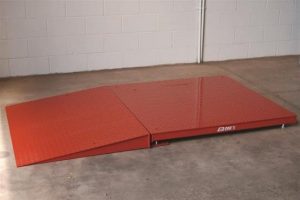

When buying a 5000lb floor scale these days, most folks tend to choose an above ground scale. If they plan on rolling a pallet jack onto the warehouse scale, they typically buy a ramp for this scale. This is generally the most cost effective weighing solution.

Basically, besides cost, there are two main reasons why you would choose one version of a industrial floor scale over the other. The #1 reason is the amount of space, the floor scale and any ramps would occupy and the #2 reason is the ease of loading products onto the scale.

Pit Type Floor Scale Advantages & Disadvantages

Several years ago, placing a floor scale into a pit was fairly common. This was mainly due to a couple of factors. Floor scales had taller profile heights and construction costs. So, putting it in a pit was less expensive. While today’s floor scales have a lower profile design, which usually eliminates the need for a pit. There are a few applications where a pit scale still makes sense.

For example, a company that needs a 4×4 floor scale with ramps on both sides, A typical ramp is 48 inches in length on each side. This type of floor scale setup will take up to 12 ft in length. That’s a lot of space that your scale and ramps would occupy. When the scale footprint needs to be smaller, putting scales into a pit might be the right decision when placing this scale into a pit. The ramps are not needed. This eliminates 4ft of ramping on each side of the scale.

Another reason for placing a floor scale into a pit is the ease of getting the product onto the scale. Because the scale is set in a pit, the transition from the floor surface to the scale is seamless. Imagine having to push a loaded pallet jack onto an above ground scale several times per day. Having a pit type scale makes this process much easier vs one with ramps.

Floor Scale with Ramp Advantages & Disadvantages

Today’s floor scales are built to have a low profile height, usually around 4 inches. When space isn’t an issue, having a floor scale with ramps may make sense. Having a longer ramp makes loading products with a pallet jack much easier.

Another reason many people choose to use an above ground pallet scale with ramp is that this setup is fairly portable. It can be moved to different parts of a warehouse or factory if needed. In our example, we’ve been mentioning ramps. However, ramps aren’t required with an above ground floor scale. You can also drive your forklift to the scale and set pallets on the scale. So, standard pallet weighing while loading and unloading the scale with a forklift is the most portable and cost effective solution.

IMPORTANT POINT REGARDING SCALE REPLACEMENT

Another variable to consider, is the potential to outgrow the size of your in-ground floor scale. An above ground floor scale can be easily replaced — without needing to backfill a 4×4 or 5×5 hole in your concrete floor!

Hopefully this information helps you make the correct decision when deciding where to put your next floor scale. Be sure to contact our sales team for buying advice and product recommendations.