Maintaining a pristine environment is absolutely critical to the success of food manufacturers. Unhygienic conditions within food manufacturing plants can have a potentially catastrophic impact on public health, not to mention the public relations and revenue impact on the company in question. It is not surprising, therefore, that increased consumer awareness and demand has seen safety standards become increasingly rigorous.

It is vital that companies manufacturing weighing equipment for the food industry ensure that the products they supply comply with best practices and meet strict legislative requirements. On a food production line, fast and accurate check weighing is vital to a company’s bottom line – the visibility of weighing data and statistics can help maximize performance and profitability – but the equipment chosen must meet stringent design requirements when it comes to construction and ease of cleaning.

With U.S. Food and Drug Administration (FDA) deadlines for small and medium sized companies to meet requirements of the Food Safety Modernization Act (FSMA) hitting in late September 2017, the industry is under pressure to deliver high quality food while also meeting the requirements of this new legislation.

The date for registered companies with greater than 500 employees to comply with the first FSMA rule Preventive Controls was September 2016. For companies with fewer than 500 employees, the compliance date was September 2017.

Why is the FSMA being implemented?

The new rules are intended to minimize the serious illness and death that can be caused by unsafe food products, by focusing on preventing food contamination throughout the entire production process.

The link between HACCP, HARPC and FSMA

Hazard Analysis and Critical Control Points (HACCP) is a systematic, preventive approach to food safety from biological, chemical and physical hazards in production processes that can cause the finished product to be unsafe. It focuses on the hazards that are unique to the product being manufactured, so the concerns for a seafood processor will be different from those of a coffee roasting company.

With the implementation of FSMA, HACCP becomes a part of a food manufacturer’s compliance to Hazard Analysis and Risk-Based Preventive Controls (HARPC). In short, the FSMA act aims to ensure the U.S. food supply is safe by shifting the focus from responding to contamination to preventing it.

Digital Weigh Scales

This risk-based, preventive approach to food safety relies on data and expertise to pinpoint potential food safety issues along the production, distribution and supply chain. The FDA has advised that facilities should set up a thorough system for documenting internal processes and record keeping, so that they can clearly demonstrate that legal standards are being met.

As a crucial element in most industrial manufacturing processes, weighing equipment for the food industry, can play an important role in FSMA adherence procedures, including, for example:

- Updating weighing equipment to more hygienic options, such as stainless steel and a fully enclosed cover for easy and efficient washdown.

- Ensuring that weighing equipment is used effectively: for instance, using checkweighers at appropriate points in the production process to obtain and record production data.

- Weighing solutions such as the ZQ375 or IP rated bench and indicators can help food suppliers to achieve both backward and forward traceability (be able to identify where all the ingredients came from and where they went).

- Using the right scales to provide the most accurate, legal for trade weights, to avoid mislabelling and eliminate costly mistakes or re-works.

- IP69K enclosures ensure instrumentation protection in heavy washdown environments.

Many companies, regardless of size, need to be looking for digital scales and weighing systems to help them to align their current HACCP and HARPC processes in order to meet FSMA requirements.

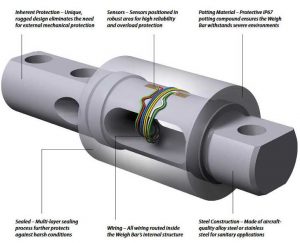

Heavy wash-down: IP69K

Equipment used in the food processing industry must be able to withstand rigorous wash-down procedures. Designed specifically to kill micro-organisms and bacteria, this heavy duty cleaning process typically uses high temperature, high pressure jet sprays and detergents. The combination of water, chemicals, high pressures and temperatures used in this cleaning process can prove fatal for electronic circuits and instrumentation.

The Ingress Protection (IP) rating system is an internationally recognized scale that relates to proven protection against environmental factors such as liquids and solids. A product with the highest rating available, IP69K, offers complete assurance that it has been subjected to a challenging set of tests to ensure protection against penetration of high pressure, high temperature water and dust particles – making it ideal for use in conditions where equipment must be carefully sanitized.

Scales designed to resist extreme temperatures

In the food industry, equipment such as check weighing scales may be subject to rapid temperature change, whether due to operating conditions or wash down procedures. Extremes of temperature inside and outside the enclosure can result in expansion and contraction of gases, which in turn can lead to moisture and humidity becoming trapped inside.

When selecting a piece of weighing equipment for use in the food industry, ensure that the manufacturer has not only recognized the challenges posed by this stringent environment, but also risen to them by incorporating design elements into the structure of the product that will counter issues such as humidity and condensation

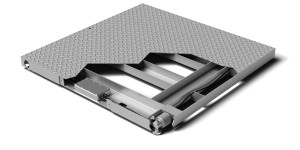

Eliminating bug and food trap areas

The process of welding two pieces of stainless steel together can have implications for the corrosion resistance of the metal. Ideally, the surfaces of your equipment/scale should be continuously welded within an inert gas atmosphere – helping to ensure that the metal remains corrosion and crack resistant and that there are no edges or un-leveled surfaces that could trap food particles or impede cleaning.

Areas of the product that have internal corners and angles of less than 135° – and which come into contact with food – should have a smooth, rounded finish to minimize food trap areas.

Scale designs should, where possible, avoid flat horizontal areas to stop water from collecting. However, in some applications, offering a flat under structure base design can be more hygienic than open tubular base frames where high pressure cleaning can cause food particles to bounce off the work surface and lodge deep inside the loadcell area, making it harder to clean.

Fully welded tubular designs can also be hard to clean. A welded structure can result in bacteria becoming trapped within the tube and thriving in the constantly changing atmosphere often found within the food industry. Conversely, base designs with flat bases and open corners ensure that any food particles can be quickly and easily washed away during high pressure cleaning.

Threads should be covered and small components such as rubber feet should be well secured and bright blue in color, allowing them to be easily located should they become detached from the scale.

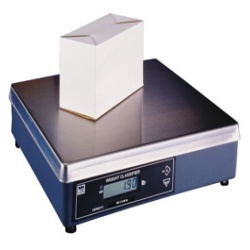

Safeguarding your business

Investing in a new digital check weigher scale is all about safeguarding quality and, fundamentally, profits – underweight packages can lead to unhappy customers, while overweight packages lead to costly giveaway and overweight shipments. When it comes to the food industry, safeguarding quality, profit and reputation must go one step further – selecting a piece of equipment that is fit for purpose is vital.

To maintain food safety and meet the requirements of the act, it may be necessary for many businesses to upgrade to equipment that is more sanitary.

Contact the sales team at Central Carolina Scale, (919) 776-7737 to discuss the products that we recommend.