The majority of this article is provided by Rice Lake Weighing Systems. We have also added a few insights and thoughts of our own as well.

What is a Load Cell?

A load cell, also commonly referred to as a transducer, converts a mechanical force into an electrical signal. Basically, the load cell bends slightly when weight is applied.

In a compression mounted load cell where the load cell is beneath the weighing vessel, like a truck scale, the load cell compresses when a load is applied. This would apply to scales like the Cardinal PRC which has the SCA load cells.

The load cell produces an analog output signal that is proportional to the applied weight or force. The load cell transmits this signal to a digital weight indicator that converts the signal into a digital weight measurement.

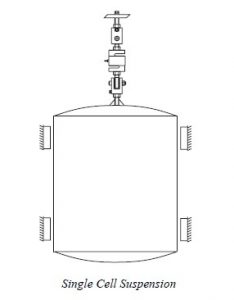

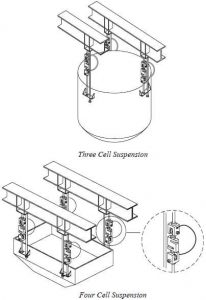

When an application requires multiple load cells, each load cell should measure the same proportion of the total load. So in a four load cell system, each load cell should measure exactly one quarter of the load.

Many load cells are proprietary to a specific manufacturer, and may require additional maintenance and costs of ownership. Carefully discuss with your scale supplier all options for load cell systems.

Analog Load Cells

The most common load cells on the market work on the strain gauge principle. All load cells need to convert their analog values to digital before the load’s weight reading can be displayed on an indicator.

Some load cells are directly cabled to the digital weight indicator where the translation occurs. Other cells are connected to summing junction boxes on the scale where the box sums analog readings from multiple load cells, converts it to a digital signal and sends that signal to the digital weight indicator.

Hydraulic Load Cells (pressure transmitters)

Unlike most other load cells, hydraulic load cells do not use strain gauges or internal circuitry. Instead, hydraulic load cells contain hydraulic fluid, and during compression, a change in pressure is created and transmitted via tubing to a summing system where the pressure is applied to an analog load cell to determine weight.

The advantages of the hydraulic load cell typically relate to being resistant to lightning damage. The disadvantage of this type of scale and replacement load cell is the cost.

Analog-to-Digital Load Cells

Some analog load cells perform the analog-to-digital signal conversion within the load cell housing. Although sometimes referred to as digital load cells, the cell still measures in analog. Making the conversion from an analog signal to a digital signal in the load cell allows the system to compare the output of individual load cells and perform a diagnostic analysis based on that information.

Some would say that because the conversion happens in the load cell, sensitive electronic components are increased throughout the scale system, making them susceptible to damage from vibration, moisture and increased solder joints.

Types of Load Cells Found in Truck Scales

Double Ended Shear Beam

This is the most widely used vehicle scale load cell configuration in North America. A double-ended shear beam load cell is a compression load cell that offers a large capacity range from 1,000 to 200,000 pounds.

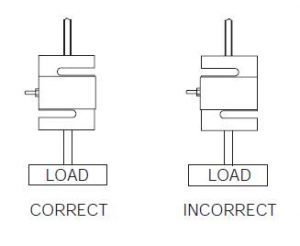

The double-ended shear beam is secured at both ends with the load applied to the center of the load cell. As in all shear beam designs, the strain gauges are mounted on a thin web in the center of the cell’s machined cavity.

The load cell also has the advantages of being less expensive in high capacity applications than the canister load cell because it does not require checking, making it virtually a maintenance free solution.

Canister

A canister load cell is the oldest load cell type. Also a compression device, it is shaped like a vertical canister and can handle loads from 100 to 1,000,000 pounds.

It is either hermetically sealed or welded to protect the gauges. This load cell’s drawbacks include the fact that it requires checking — installing check or stay rods to hold the weighing vessel in place on the load cell’s top plate during weighing.

For these reasons, many canister load cells on the market today are used to replace older canister load cells on existing weighing systems.

Rocker Column

Some manufacturers prefer rocker column load cells because they are inexpensive. However, they require check rods and bumper bolts that require maintenance, increasing your cost of ownership. The cost saved by the manufacturer on the raw material is passed down the line to the end user in the form of additional maintenance.

Load Cells Are Usually Manufactured as either Alloy Steel or Stainless Steel

Truck scale load cells are generally made of stainless steel or alloy steel, but most manufacturers offer a variety of load cell solutions that best fit your application needs.

Alloy Steel Load Cells

Load cells manufactured from tool alloy steel elements are by far the most popular cells in use today. The cost to performance ratio is better compared to either aluminum or stainless steel designs. The most popular alloys are 4330 and 4340 because they have low creep (the change in load cell output over time while under load) and low hysteresis (the difference between load cell output readings for the same applied load).

Stainless Steel Load Cells

Stainless steel cells are more expensive than tool alloy steel load cells. They are sometimes fitted with hermetically sealed web cavities, which make them an ideal choice for corrosive, high-moisture applications. Stainless steel load cells that are not hermetically sealed have little advantage over comparable cells constructed of tool alloy steel, other than a higher resistance to corrosion.

We hope you enjoyed learning more about the different load cells found in the average truck scale. Since 1980 we have been providing customers throughout the central part of North Carolina with truck scale inspections, scale repair and calibration services. Our test weights and weight cart are certified by the state of North Carolina for accuracy. Our scale technicians are highly trained and knowledgeable when it comes to checking and installing various brands of truck scales.

If you need your existing scale checked or perhaps you’re in the market for a new truck scale, please give us a call today (919) 776-7737.