Have you ever driven by a truck weigh station on the interstate? Or maybe you’ve driven by a feedmill and noticed a seventy foot long truck scale out front? The odds are that most of us have done one or the other of the scenarios above. So, how do truck scales work that are sitting beside the highway or beside the recycling center?

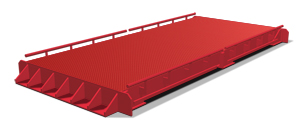

A truck scale is a large set of scales typically installed permanently on a concrete foundation. By weighing the vehicle both empty and when loaded, the load carried by the vehicle can be calculated. Typically the truck scale will have multiple load cells underneath the platform.

How do Truck Weight Scales Work?

Truck scales are used to measure the weight of a vehicle and its contents. Vehicle scales are used in many industries such as metal recyclers, waste facilities, truck stops, landfills, and rock quarries etc… to weigh heavy vehicles such as dump trucks, semi-trucks and trailers.

Truck scales typically consist of several large platforms. These platforms are often called the weighbridge. The weighbridge is supported by multiple load cells, which are sensors that measure weight. There are typically three choices of load cell technology. Analog, Digital, or Hydraulic.

When a vehicle drives onto the scale weighbridge, the load cells measure the weight of the vehicle and its contents. The weight is then displayed on the scale digital readout with truck id numbers. At this point, a ticket is printed showing the gross weight of the truck. And in many cases, the ticket will also show the tare weight and net weight as well. There are many options to consider.

Some truck scales also have additional features such as a weigh-in-motion system, which allows the scale to measure the weight of a slowly moving vehicle. Or, some truck scales include a self-service kiosk, which allows the driver to enter their information and print a weight ticket which can be used for record keeping purposes or to verify the weight of the vehicle and its contents for shipping or other purposes.

Importance of Accurate & Reliable Truck Weighing Equipment

Overall, truck scales are a vital tool for ensuring the safety and efficiency of the transportation industry. So when you wonder how do truck scales work, the answer is a truck scale is a large weighing platform with load cells underneath that allows trucks to be accurately weighed. And, by accurately measuring the weight of vehicles and their contents, these vehicle scales help to prevent overloading and other potential hazards on the road. Whether you’re a truck driver, a shipping company, or a business owner, a reliable truck scale is an essential component of your business operations.

Our

Our