It may be tempting to save a few dollars by purchasing an inexpensive floor scale imported from overseas. After all, the capacity and size may appear to be the same as the more expensive brand and the pictures of the products look virtually identical! So, what is it that really separates the Expensive Floor Scale and makes it better than the Less Expensive Floor Scale?

Imported Floor Scales Worth the Hassle?

This is something we’ve discussed before actually. We’ve seen just about every possible brand of platform scale over the years. Some of the scales shipped over from China are decent. Some aren’t as good. Some of the weight indicators are not very user friendly or reliable.

When it comes to floor scales, we generally rank them in different levels of floor scale quality. For example, top of the line would be the B-Tek Clydesdale or Rice Lake Roughdeck. Second level might be the Pennsylvania 6600 or Digi Summit 3000. Third level might be a Brecknell floor scale. Lowest level would be brands & models that we won’t mention…

Do I Need Legal for Trade?

First thing that you want to determine is NTEP legal for trade status. You will need to determine if your floor scale needs to be legal for trade. Some cheap floor scales you find on the internet are not legal for trade. It’s almost always a good idea to buy a legal for trade floor scale. In our opinion, it’s a good idea to purchase a platform scale that is capable of earning a Certificate of Conformance (CoC#).

Quality Scale Components Make a Difference

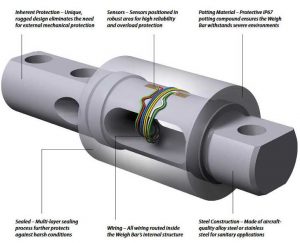

Next, compare the electronic components that make up the scale There are typically four load cells in each floor scale, one in each corner. Some lower-quality floor scales use load cells that you cannot replace just one of the cells. When checking for causes of scale weight error, if one goes bad, all four need to be replaced! Some manufacturers also use cheap load cells that are sourced overseas and have little if any documentation. It is important to use quality components to ensure longevity and accurate weighing. Some of the load cell brands we recommend include Revere Transducers and Rice Lake Weighing Systems among others.

Next, is the Junction Box with Summing Board. Does the scale you are considering have a junction box with summing board inside? The purpose of the junction box is so you can adjust the output of the loadcells so the scale weighs the same regardless of where the load is placed on the scale platform. If a loadcell needs to be replaced the junction box allows you to easily remove the bad cell and replace it with the new one and wire it back into the scale without having to unwire and re-solder all the cells back together. Some cheap platform scales just tie the wires together and eliminate the junction box in their design. We do not recommend this and it makes replacing a load cell and/or troubleshooting difficult.

Heavy Duty Steel Platforms Can Last for Many Years

Maybe equally as important as the scale components is the build of the scale itself — The steel weighbridge. Pay attention to the shipping weight of the scale. The heavier the scale typically means the better build quality.

Thicker deck plate and substructure is an important key to giving the load cells the structure they need to perform properly. If the floor scale is flexing and bending, the scale will not last and it will cause inconsistent weights. Thin, short welds are also a sign of mass-produced low-quality scales. These welds could break over time and cause inconsistent weights and/or significant down-time.

Weight Displays are an Important Part of the Scale System

The last item, and possibly most important to consider, is the indicator that comes with the floor scale. Is an indicator included in the price? If it is, there are a few questions to ask. Is the indicator calibrated to the scale base? Does the indicator include a user manual that is easy to read and understand? Do you need a certificate of calibration with certified weights for your ISO program? Do you need a full numeric keypad to enter a tare weight? Do you want to tie your scale into a computer or printer?

These are all common issues people come across when purchasing a cheap floor scale online. And, many times this leads them to spending significantly more money with their local service company to get their scale up to the actual functionality they need.

In our experience, customers usually experience a better overall scale buying experience by contacting an experienced scale sales person first. Price and budget can certainly be an important component. But, scale construction, quality components and more can also be considered as well. By working together with a scale company, you get the type of industrial floor scale that you actually need. You also get any custom features that you may require.

As always, Central Carolina Scale would like you to make the most informed decision possible to help your business. We are here to help you with any questions you may have to help guide your decision.