We have been selling floor scales literally since the early 1980’s, so we know a thing or two about what floor scale options and features you might want to consider. Of course back in the 80’s almost all your floor scale choices were built in the United States. Fast forward to today and that is not always the case. So, what are the top four options to consider on a floor scale? Let’s take a look.

Battery Powered Floor Scales

Most standard floor scales on the market come standard with standard 110 VAC power. And, most of the time this works fine. However, there are some situations where a battery powered industrial floor scale makes perfect sense. For example, what if you’re planning on the placing the scale in a shelter that is a hundred feet away from your main building? Or what if you’re weighing is a very important part of your business and you need to make sure your floor scale is operational even if the power goes out? Luckily in most cases it’s not very expensive to add battery power to a floor scale. However, please note that it is usually much easier to order the scale with a battery powered digital weight indicator as opposed to swapping indicators down the road.

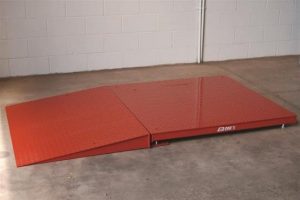

How are You Going to Weigh Items on the Floor Scale?

Before you purchase the floor scale, think about the flow of your warehouse. How are you going to weigh your pallets or whatever it is you are looking to weigh? Do you need to cut a hole in your floor and put in a pit frame and place the floor scale in the floor? Or do you need to buy the floor scale and order a ramp at the same time? If you choose a ramp, you will need to factor in how much overall floor space you will need since in most cases a ramp is going to be either 48″ x 48″ or 60″ x 48″ each. So once you have a 60″ x 60″ scale and then add a 60″ x 48″ ramp, you will need a lot of warehouse space to accommodate that.

Do You Need a Portable Floor Scale?

Maybe you already decided that you need battery power…. Do you need to take the next step and purchase a truly portable floor scale? Now you can move just about any standard floor scale with a forklift. But it does require you to be careful and not rip the homerun cable out of the scale display. However, today we have numerous ways to make a heavy duty industrial floor scale truly portable. We have portability carts, portability frames, and we have forklift channels that can be built into the side of the scale platform. Any of these scale options can make moving your floor scale around your warehouse much easier and safer.

Do You Need to Connect Your Floor Scale to a Printer or Your Computer?

Most floor scale customers are just looking to purchase a four by four foot square shaped scale for weighing pallets. However, quite a few customers could benefit from adding an additional element to their weighing. When you’re looking to purchase a floor scale why not go ahead and add a label printer to the scale? With a label printer, you could easily add a label to everything that you weigh including things like the gross weight, maybe a tare weight and a Net weight. You could even add the time and date of the weighment if you wanted to. Also, in a similar situation, you could also look into having your weighments be sent to your computer. We have several different ways to send scale weight data to your computer.

Conclusion

I hope this entry has been helpful for you. These top four options to consider when purchasing a floor scale are based on many years of customers buying floor scales and listening to their requests and what they actually purchased. Of course, there are other things to consider as well like NTEP certification, industrial heavy duty versus light industrial, imported floor scale versus made in America, etc… but once you get those things figured out, these four options that I mentioned above are important to think about.

Please contact us with your questions or request for quote. You can call, email. or complete the RFQ form on our website. Thanks for visiting our website and I hope that you will consider us for your next weighing equipment purchase.

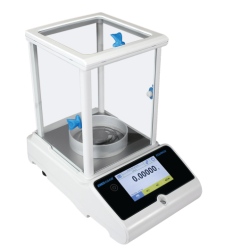

The Aqua stainless steel scale lineup offers check weighing, percentage weighing and parts counting, while the Gladiator range offers those as well as check counting, dynamic/animal weighing, and a helpful Hold function.

The Aqua stainless steel scale lineup offers check weighing, percentage weighing and parts counting, while the Gladiator range offers those as well as check counting, dynamic/animal weighing, and a helpful Hold function.