A truck scale is a rather large investment for most businesses. So, it’s one of those purchases that you want to take your time with and do your homework. Needing a truck scale in a hurry is not a good situation to be in. Especially since most purchasing managers have never been involved in choosing and installing a 70 or 80 foot long scale for weighing trucks. So, you’re probably wondering what mistakes should folks avoid? Well here are a few to think about.

Lack of Planning

A truck scale is a rather large investment. It also takes time from start to finish. It also has multiple key moments. The customer needs to have a manager or point of contact. Ideally one or two people. Questions and timelines will come up.

Folks will ask, when is the truck scale arriving? Do we have power at the scale location? Are all the cables and conduits ready? Is the customer ordering the crane to offload the scale? When does the crane need to be there? Is the foundation ready for the scale? The point of contact and the scale sales person / installer need to discuss the timeline so there are no huge surprises.

Overlooking the Scale Foundation

Most customers around the Carolinas are going to choose an above ground truck scale. Back in the day customers would choose a mechanical truck scale and it would be installed in a pit since it had levers and took up a lot of space. However, that was back then… Most customers today choose to have a concrete foundation poured and place the scale on that. Otherwise, you are having to dig a hole and pour a lot of concrete. And of course the pit is going to collect a lot of water and then you’re looking at drains and pumps and that is usually not what we would recommend in most cases.

You do want to make sure that you or the scale company use a reputable concrete person to pour and form the scale foundation. The last thing you want is the foundation cracking and not able to withstand the weight of the truck scale the trucks being weighed.

We have also seen situations where a potential scale buyer doesn’t have a good grasp on the location around where the scale will be located. There could be environmental issues as well as things like drainage lines nearby, etc…

Overlooking the Scale Location

Deciding where to place your new truck scale can sometimes be really easy and other times can be very challenging. It can be even more difficult when you have a half dozen folks involved with the truck scale buyer. Sometimes it can be a good idea to put someone in charge from your company so there aren’t too many folks involved in the decision making.

Generally speaking with truck scales, you want to place the scale in the correct area for your traffic flow. You also need to try hard to not place the scale in a low area where water is going to bring all kind of debris. One of the biggest problems that above ground truck scales struggle with is buildup that gets lodged under the weighbridge.

Not Choosing the Proper Load Cell Technology

In most situations these days, a truck scale buyer has three distinct types of technology to consider. Hydraulic, Digital or Analog truck scales. Each has it’s place. We suggest that you discuss these options with your scale sales person to determine which is best for you.

Choosing the Wrong Scale Platform

Likewise, you also need to choose the scale platform material. Truck scales are exposed to various environmental conditions, including extreme temperatures, snow, ice, heavy rain… and on top of that possibly heavy traffic everyday!

If you are placing a truck scale in certain environments like HEAVY amounts of daily traffic or possibly weighing really corrosive materials… you might want to discuss this with your scale sales person first before you actually purchase the scale. If you discuss this first, you can likely take care of this with solutions like possibly a concrete scale deck instead of steel. Or you can perhaps get the “HD” version truck scale instead of just the “standard duty” version.

Not Slowing Down & Thinking About the Scale and Your Trucks

Before you place the order for a truck scale, be sure to measure your trucks and be certain what size scale you need. And, what about truck scale accuracy? Most customers choose a 70, 80 or 100 foot long truck scale. Width is normally 11 feet wide. The other thing to think about is the number of trucks you expect to be weighing daily. Think about what this number will be five years from now. In other words if you think that you’ll be weighing well over 250 trucks a day, don’t buy a light duty truck scale.

Not Choosing the Right Scale Company

Over the forty plus years we’ve been in business we have installed and worked on A LOT of truck scales. You name the town and we have probably worked on one near there. We have installed digital truck scales, analog truck scales, and even hydraulic truck scales. We’ve even had competitors tell customers that we’re out of business, just so they can sneak in and take the sale. Maybe we’ll talk about that in more detail some time…. but continuing on.

In our opinion, these days too many purchasing managers or QC managers worry about certain certifications and not enough about proven experience. Think about it, who would you want installing your truck scale… two state certified scale technicians who have a combined 35 years of experience OR two scale technicians with maybe 10 years of experience total, but with lots of badges and approvals that they might have earned by watching a video. We’ll take the experienced techs everyday!

Not Investing the Money… The Scale Should Last for Decades So Spend the Money

Look, we all shop the internet for deals. All of us can find cheaper items for just about everything. Just remember, this truck scale that you’re looking to purchase is designed to last you for decades. Don’t be afraid to spend a little more money now to get a scale that might last an extra five or ten years. We see cheap scales everyday. There are some scale manufacturers overseas that can cut corners like you wouldn’t believe! But do you really want to purchase a cheap truck scale that is built on price and reaching a certain “price point”?

Focus on quality and the overall truck scale lifespan. Remember this is a scale that is going to have 80,000 lb vehicles driven over it everyday for years. Add in the outdoor elements and you want to make sure you buy a quality product that can last you two or three decades. Many times when customers choose a low end truck scale they often have to replace the scale much earlier than they would have with a traditional high quality truck scale.

Conclusion

Buying a truck scale whether it’s a 70 foot or 100 foot long is a large investment. It’s something that most folks only do once or twice in their professional career. Try to avoid the mistakes when purchasing a truck weighing scale that we have presented in this entry. By avoiding some of these common oversights many of you should be able to choose a high quality truck scale that will provide you with decades of quality weighing. If you would like to get buying advice or price quotes from us, please complete the RFQ form and we look forward to working with you.

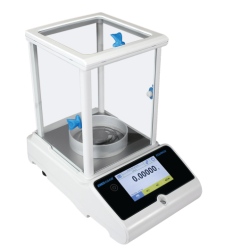

The Aqua stainless steel scale lineup offers check weighing, percentage weighing and parts counting, while the Gladiator range offers those as well as check counting, dynamic/animal weighing, and a helpful Hold function.

The Aqua stainless steel scale lineup offers check weighing, percentage weighing and parts counting, while the Gladiator range offers those as well as check counting, dynamic/animal weighing, and a helpful Hold function.